RCCB Overheating: Causes, Consequences, and Prevention Strategies

Residual Current Circuit Breakers (RCCBs) are essential safety devices designed to protect against electrical shock and fire hazards by detecting earth leakage currents. However, these critical safety components are themselves vulnerable to overheating, which can lead to catastrophic failure, fires, and loss of electrical protection. This whitepaper provides a comprehensive analysis of RCCB overheating phenomena, examining the fundamental causes, serious consequences, and effective prevention strategies based on current industry standards and research findings.

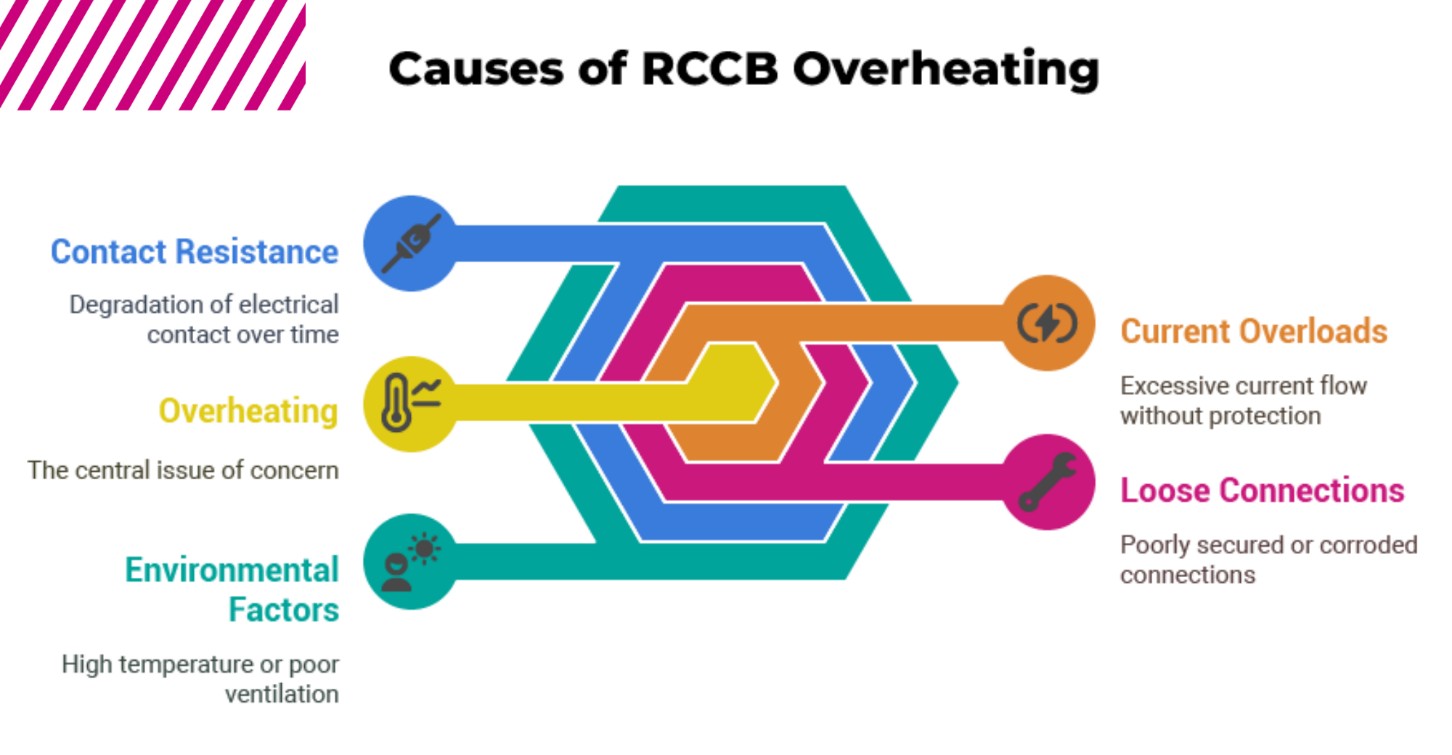

The primary causes of RCCB overheating include lack of integrated overcurrent protection, loose terminal connections, contact resistance degradation, and adverse environmental conditions. When overheating occurs, the consequences can be severe, ranging from internal component failure to complete device destruction and fire hazards. Prevention requires a multi-faceted approach including proper device selection, correct installation practices, regular maintenance, and environmental control.

Introduction

RCCBs operate on the principle of detecting imbalances between live and neutral currents, typically tripping at residual currents as low as 30mA to provide protection against electric shock. While these devices excel at their primary function of earth fault detection, they possess an inherent vulnerability: they lack integrated overcurrent protection, making them susceptible to thermal stress that can compromise their operation.

The significance of RCCB overheating extends beyond individual device failure. In modern electrical installations, RCCBs are critical safety components whose failure can eliminate essential protection against electric shock and fire hazards. Understanding and preventing RCCB overheating is therefore essential for maintaining electrical safety in residential, commercial, and industrial applications.

Fundamental Causes of RCCB Overheating

Lack of Integrated Overcurrent Protection

The most fundamental cause of RCCB overheating stems from their design limitation: RCCBs are not equipped with integrated overcurrent protection. Unlike RCBOs (Residual Current Breakers with Overcurrent protection) that combine earth leakage detection with overcurrent protection, standard RCCBs rely entirely on external protection devices.

This design characteristic creates a critical vulnerability where the maximum possible operating current must not exceed the rated current of the fault current protection device. When this fundamental requirement is violated through installation errors, load growth, or coordination failures, RCCBs can carry currents beyond their thermal design limits without any internal mechanism to disconnect themselves from the circuit.

Contact Resistance and Aging Effects

RCCBs experience progressive contact resistance degradation over time due to repeated switching operations, arcing, and environmental factors. When contacts repeatedly open and close under load, arcing occurs between the contact surfaces, gradually degrading their conducting properties and increasing resistance at the contact interface.

This degradation creates a self-perpetuating cycle where increased resistance leads to higher power dissipation through the relationship P = I²R, generating additional heat that further accelerates contact degradation. Research indicates that thermal contact resistance can increase by 185% to 300% over extended periods of exposure to elevated temperatures.

Environmental Temperature Effects

RCCBs are highly sensitive to ambient temperature conditions, with most devices rated for operation between -25°C and +55°C. When ambient temperatures exceed these limits, internal components experience thermal stress that can lead to overheating.

Installation and Grouping Effects

When multiple RCCBs are installed side by side in enclosed panels, thermal interaction between devices can cause cumulative heating effects. The heat dissipation of one device affects neighboring units, potentially causing overheating when adequate ventilation is not provided.

Poor installation practices significantly contribute to RCCB overheating, particularly loose terminal connections that create high-resistance points generating localized heating. The problem is exacerbated by the fact that RCCBs do not protect from the overheating that strikes if conductors are not screwed into terminals.

Arc Formation and Extinction Issues

During switching operations, arcs may form between RCCB contacts, particularly if the device is switched off under load. While RCCBs are not primarily designed to break load or fault currents, improper application or upstream protection failure can subject them to such conditions. If the arc extinction mechanism operates inefficiently or is overwhelmed by excessive current, the resulting arc can produce intense heat—potentially exceeding 6000°C—which may damage internal components and lead to enclosure deformation or fire. Proper coordination with overcurrent protection is essential to prevent such occurrences.

Serious Consequences of RCCB Overheating

Internal Component Failure and Device Destruction

Overheating causes progressive degradation of internal RCCB components, including the differential current transformer, relay mechanisms, and contact assemblies. Extended exposure to high temperatures can cause insulation breakdown, contact welding, and permanent damage to the tripping mechanism.

Fire Hazards and Safety Risks

Severe overheating in RCCBs can lead to internal fires, with burning gases and particles potentially erupting through the device casing. In the documented incident, a boilermaker attempting to reset an RCCB experienced electrical burns when the device failed internally and burning materials erupted through the casing.

Thermal runaway conditions can lead to complete RCCB destruction, with intense heat generated during failure potentially damaging not only the RCCB itself but also adjacent components, wiring, and electrical panel housing. The cascading effects can ignite surrounding materials and propagate fires throughout electrical installations.

Loss of Critical Safety Protection

When RCCBs fail due to overheating, entire electrical circuits lose their earth fault protection, leaving electrical systems vulnerable to dangerous conditions that could cause electric shock, equipment damage, and fires. The loss of protection is particularly dangerous because it may not be immediately apparent to users.

This situation creates a false sense of security where users believe they have residual current protection when the device has actually failed due to thermal stress. The consequences can be fatal if earth faults occur after RCCB failure, as there is no backup protection against electric shock.

Economic and Operational Impact

RCCB failures due to overheating result in costly equipment replacement, system downtime, and potential damage to connected loads. In industrial settings, such failures can cause production interruptions and safety violations. The cascading effects of RCCB failure often exceed the cost of the device itself, including investigation costs, replacement parts, and lost productivity.

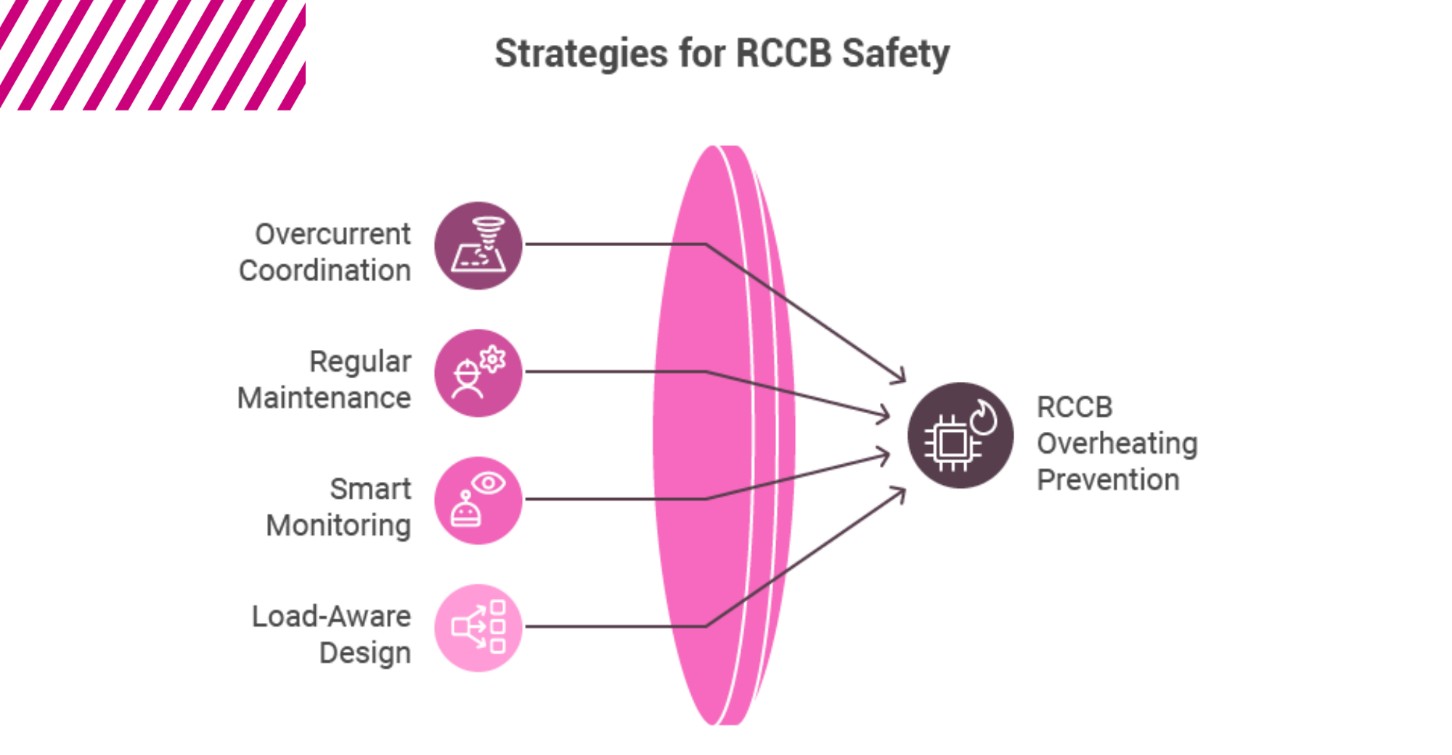

Comprehensive Prevention Strategies

Proper Device Selection and Rating

Selecting RCCBs with appropriate current ratings is fundamental to preventing overheating. The rated current must accommodate not only normal operating load but also consider potential peak demands and inrush currents from connected equipment.

Another important topic is the selection of the type of residual current sensitivity and the value of rated residual current, both of which we shall cover in our following blog posts.

Mandatory Overcurrent Protection Coordination

Since RCCBs lack overcurrent protection, they must be used in series with MCBs or fuses rated at least one step below the RCCB's maximum current capacity..

Proper coordination ensures that overcurrent conditions are cleared before they can cause RCCB overheating. Protection can be obtained either with fuses or with MCBs (per each phase, with maximum rated current lower than rated current of the RCCB).

Installation Best Practices

Correct installation practices are essential for preventing RCCB overheating. RCCBs must be installed in dry, well-ventilated locations with adequate spacing between devices.

Proper wire termination with appropriate torque specifications prevents loose connections that could lead to overheating. All connections should be made according to manufacturer specifications and inspected regularly using appropriate testing equipment.

Load Management and Circuit Design

Proper load distribution prevents individual RCCBs from carrying excessive current. High-power loads should be distributed across multiple circuits, and consideration should be given to load diversity factors. However, regulations explicitly state that overload protection shall not solely be based on the use of diversity factors of the downstream circuits.

Inrush current limiting devices may be necessary for circuits with significant motor or capacitive loads. Circuit design should account for potential load growth and ensure that RCCBs are not operated near their thermal limits under normal conditions.

Regulatory Framework and Standards

International Standards Compliance

RCCBs must comply with international standards such as IEC 61008 and EN61008, which specifies requirements for residual current operated circuit-breakers without integral overcurrent protection. These standards define operating temperature ranges, thermal testing requirements, and performance criteria under various environmental conditions.

Temperature rise testing according to IEC 61008 and EN 61008ensures that RCCBs can operate safely within their specified thermal limits. Manufacturers must provide heat dissipation data and operating temperature specifications to enable proper application and derating, if there are needed.

Thermal Analysis Research

Academic research on RCCB thermal and electrodynamic risk has revealed that "at a relatively high prospective short-circuit current even an overcurrent circuit breaker rated significantly less than the replaced fuse can contribute to damage of the back-up protected RCCB.

Source: Thermal and electrodynamic rist of RCCB

This finding emphasizes the complexity of proper coordination and the need for thorough analysis rather than simple current rating comparisons.

Laboratory testing of cut-off currents and Joule integrals of overcurrent circuit breakers has shown that thermal and electrodynamic exposure varies significantly with different breaker characteristics. The research concludes that "assessment of the respective exposure is difficult without additional laboratory tests".

Economic Impact Assessment

Cost of RCCB Failures

RCCB failures due to overheating can result in costs far exceeding the device replacement cost. In industrial applications, unplanned downtime due to breaker failures can result in "significant costs and lost productivity". The consequences include frequent breaker tripping, equipment downtime, and substantial financial losses.

Replacement components are often not readily available or require lengthy lead times, extending downtime and increasing economic impact. The cascading effects include investigation costs, emergency repairs, and potential safety violations that can result in regulatory penalties.

Return on Investment for Prevention

Implementing comprehensive RCCB overheating prevention strategies provides significant return on investment through reduced downtime, improved safety, and extended equipment life. Predictive maintenance systems enable planned maintenance during convenient windows rather than emergency repairs during critical operations.

The cost of implementing proper overcurrent protection coordination and environmental controls is minimal compared to the potential cost of catastrophic RCCB failure. Smart monitoring systems provide additional value through improved system visibility and proactive maintenance capabilities.

Conclusions and Recommendations

RCCB overheating represents a significant safety concern that can lead to device failure, fires, and loss of electrical protection. The primary causes include lack of integrated overcurrent protection, contact resistance degradation, environmental factors, and installation deficiencies.

Prevention requires a comprehensive approach encompassing proper device selection, mandatory overcurrent protection coordination, correct installation practices, regular maintenance, and environmental control. The regulatory framework increasingly recognizes these requirements, with modern electrical codes mandating appropriate overload protection for RCCBs.

Key Recommendations

- Implement Mandatory Overcurrent Protection: All RCCBs must be protected by appropriately coordinated overcurrent protective devices with ratings below the RCCB's thermal capacity.

- Establish Regular Maintenance Programs: Monthly testing and annual thermal inspection programs should be implemented to detect developing problems before they cause overheating.

- Ensure Quality Installation: Proper installation with appropriate torque specifications, adequate ventilation, and quality connection materials is essential for preventing thermal problems.

The electrical industry's recognition of RCCB overheating as a significant safety concern has led to important regulatory changes and improved industry practices. However, continued vigilance and proper implementation of prevention strategies remain essential for maintaining electrical safety and preventing catastrophic failures. Regular monitoring, proactive maintenance, and adherence to established standards represent the cornerstone of any effective RCCB overheating prevention program. As electrical systems become increasingly complex and critical, the importance of reliable RCCB operation cannot be overstated.